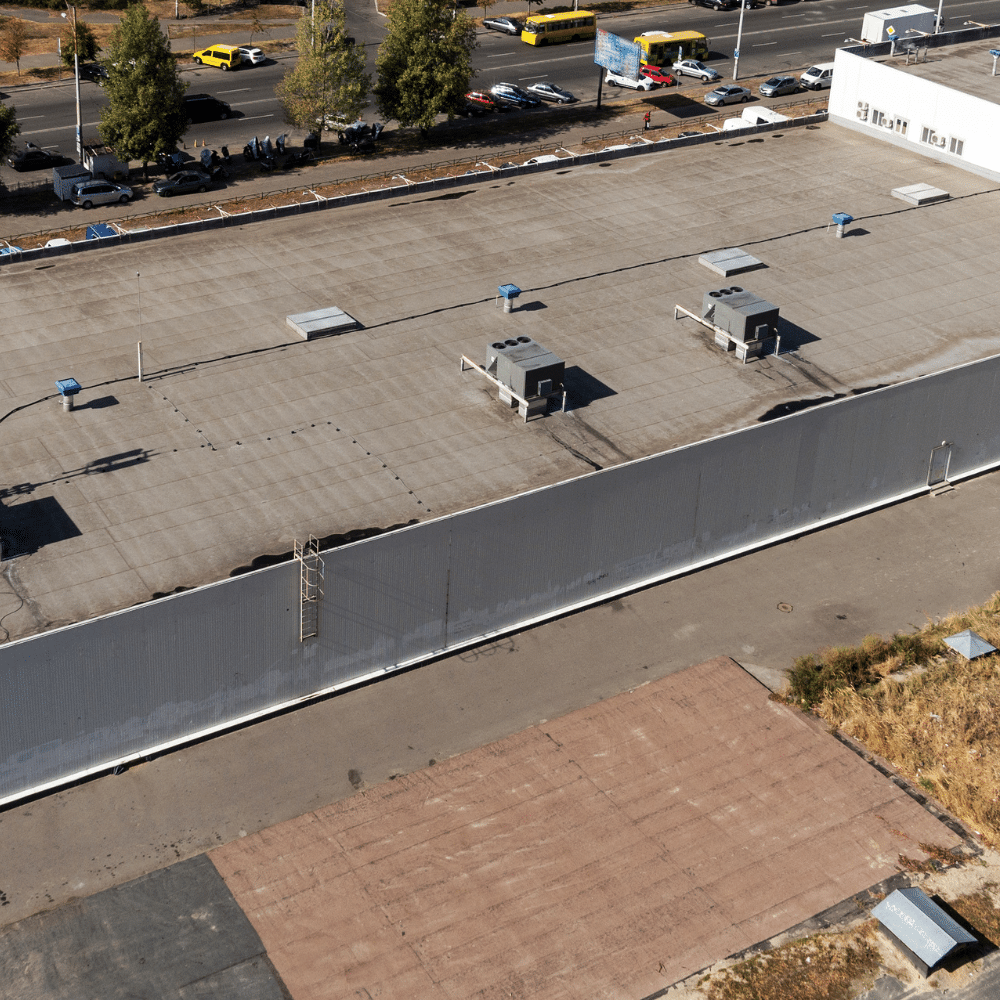

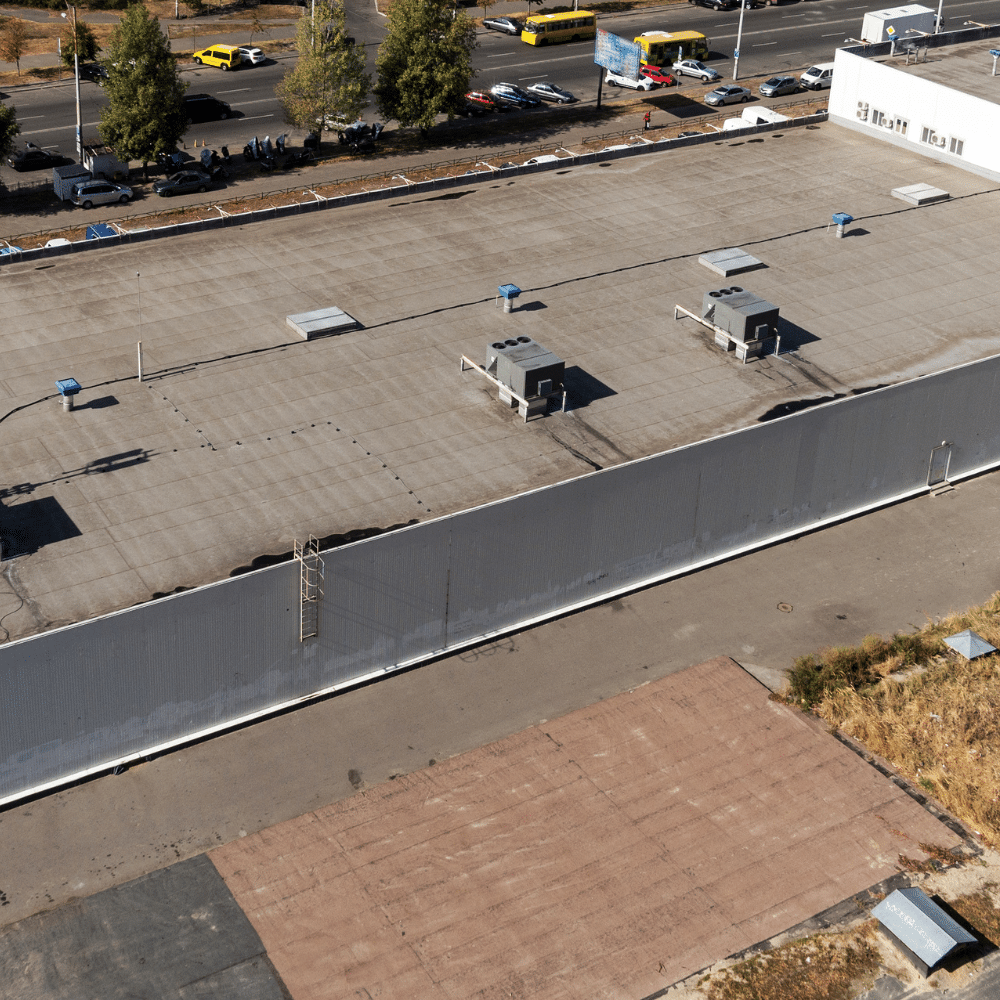

However industrial facilities are rarely in a position to have the roof completely replaced. With the additional costs, the potential for disrupted work makes it unlikely. The need to protect interior surfaces before roofing work is done can add weeks to the overall project timeline.

While there’s no replacement for a structurally sound roof, there are ways to make sure your current roof performs at its best. One way to do this is by installing a Professional roof coating. These can be applied quickly and can offer you long-lasting results. Industrial roof coatings are also cost-effective. You may be able to coat your entire roof for the funds you would have to spend replacing even a quarter of your roof, to say nothing of the cost of work slowdowns.

Here are the biggest benefits that make quality coatings a great investment:

1. Improved the Longevity of the Roof:

With any work you do on the roof, longevity is what you are striving for. The average residential roof can cost about $830 to repair, and the high standards that are required of an industrial roof can mean that they cost even more. Once those repairs start and become frequent, then it typically means a downward spiral for the roof is coming.

Industrial coatings can apply anti-UV, anti-corrosion, and waterproofing protection to your roof. By acting on these essential risk factors, you could save hundreds or even thousands of dollars in the coming years. Depending on your roofing materials, coating and maintenance can add five years or more to a roof’s life.

2. Reduced Facility Energy Usage

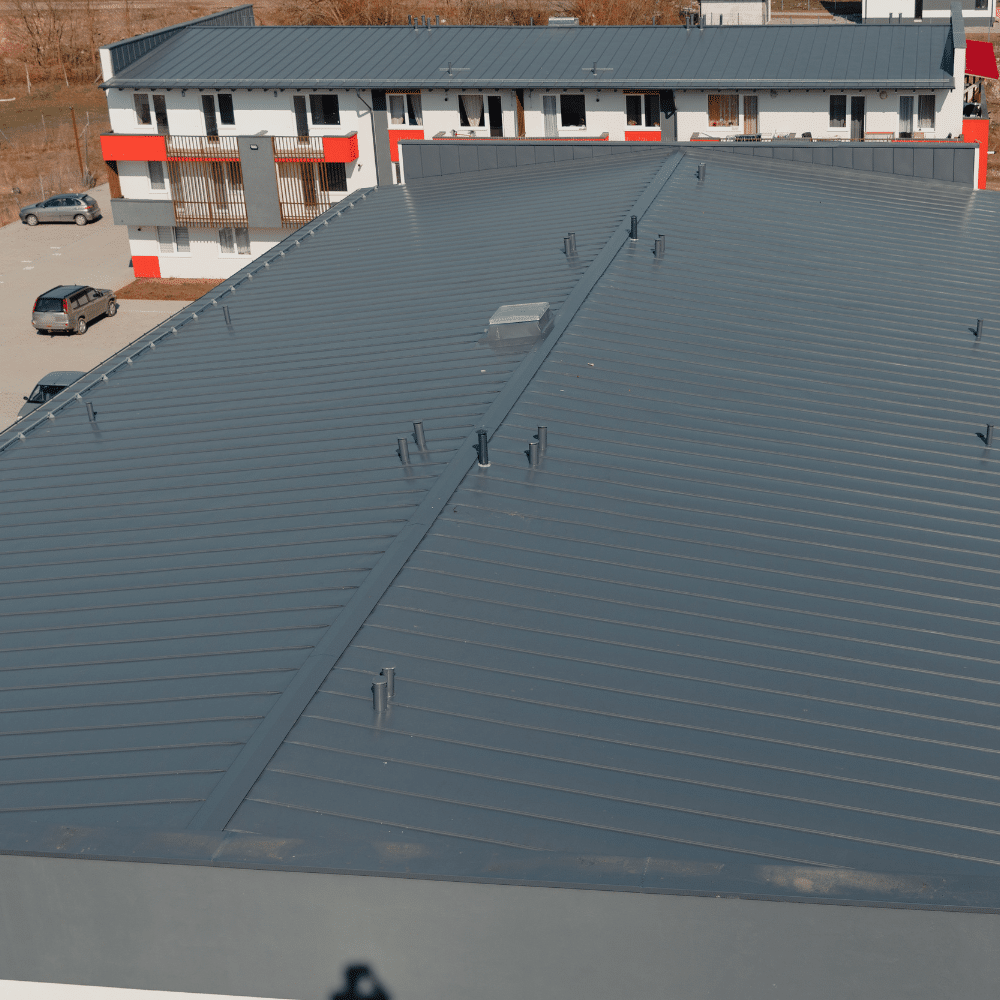

The roof is one of the major determinants of energy usage within your facility. The surface area presented by your roof can reflect large quantities of solar radiation, potentially making it much easier to maintain the operating temperatures you need. That remains true no matter if it’s hot or cold outside. The metal roof of the average industrial facility is well-positioned to achieve savings. But to achieve this, the roof needs to be fully intact and free of corrosion. Heat transfer properties of the roof change as it becomes warped or imperfections develop on the surface. Proactive use of industrial coatings is the key to maintaining surface integrity over the long haul.

3. Improving Aesthetics and Lower Fading

Roof fading can make your building look old and worn out quicker than it should. Roof coatings can help keep your building looking fresh for a longer period of time. This makes a big difference if aesthetic considerations are important to your leadership or other stakeholders who keep your business moving.

Once the paint starts to chip on a roof, it usually leads to a domino effect that results in heavy maintenance and repair costs. It might take only a day to apply coatings that will halt this process in its tracks. With a versatile array of coatings to choose from, there are plenty of options for prefinished and metal surfaces.

4. Greater Weather Resistance

No matter the climate, the weather is a driving factor in how well your facility’s exterior stands up over the years. That is especially true in New England. We experience so many different weather changes throughout the year. If you are in a coastal area then you have to contend with the salt attack from sea breezes and even inland communities can suffer severe rain and wind throughout the summer.

Industrial waterproofing coatings help you create the tight seal you need to prevent moisture intrusion in and around your roof. A small leak can compromise your interior walls even if damage isn’t apparent right away, opening the door to future issues. Coatings make up part of your first line of defense.

5. Defense Against Exterior Growth

In hot, humid environments, mildew and algae can grow on building exteriors. These unsightly black, green, or blue patches can take root on the roofs and then will work their way across the walls. The potential for damage is limited, but they can be cited as a safety or sanitation failure in your workplace safety policies.

While an industrial metal roof offers some protection, industrial roof coatings can extend it to a whole new level. They create an inhospitable environment for unwanted growth, especially on the shady side of structures where vulnerability is high. That may save you the trouble of pressure washing every year.

Add Industrial Roof Coatings to Your Building Maintenance Strategy

Coatings already protect your sensitive interior surfaces, expensive equipment, and even the structural members of your building. Your roof isn’t just “out of sight, out of mind” – it deserves the same level of careful attention. As part of your total maintenance strategy, rooftop coatings can help you achieve your goals in savings, efficiency, and safety facility-wide.

Superior Seamless Roofing

At Superior Seamless Roofing, we stand behind the very best commercial roofing systems, which is why we recommend ASTEC roofs to our commercial clients. As the only contractors in all of Connecticut authorized to install ASTEC roofing systems, we’re dedicated to equipping the United States with the best in commercial roofing as commercial roofing contractors.

Once you know the kind of roof coating you need for your application, you’ll want to find a brand or manufacturer that supplies quality roof coatings that provide your desired results. Our Expandothane is another product we recommend produced by Dow Chemical offers high corrosion resistance, hail resistance, excellent physical properties, and waterproofs your roof. Contact the experienced team at Superior Seamless Roofing if you are considering waterproofing your roof. We’ll make honest recommendations that fit your buildings needs.